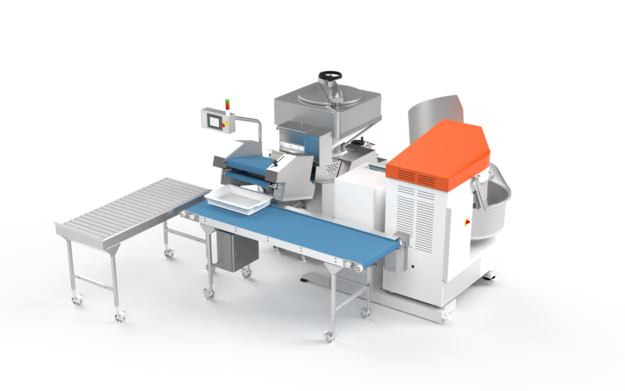

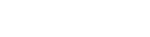

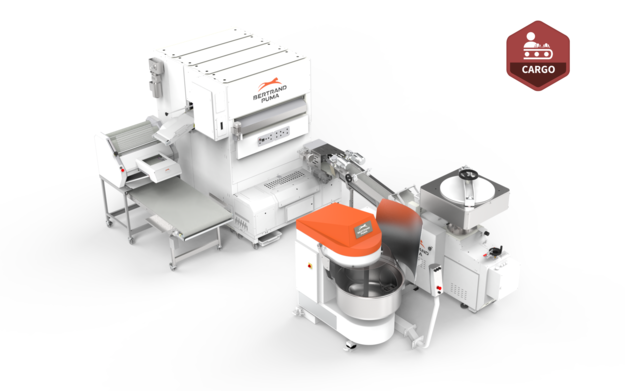

DOLINE - AUTOMATIC TRAY LOADING SYSTEM

DOLINE is an automatic stainless steel bread-making unit, designed for loading dough into dough trays after kneading. The dough, introduced either manually or via a selftilting mixer, is automatically weighed, divided and placed in trays.

The system is compatible with all types of dough, with or without fillings, and can be set up to work with different sizes of dough trays or flat trays.

How does it work?

With a production rate of 1 to 6 trays/min, Doline can calibrate trays from 1 to 7 kg. The dough is poured into a pressurized hopper, then weighed and automatically divided into several pieces (up to 6 pieces). These dough pieces pass under a heavy bar conveyor belt, then into a rolling machine, to be gathered together (they will be reformed during the proofing stage) until they reach a total weight determined by the operator. They are then placed in trays, ready for proofing.

Doline is perfectly suited to our Divitrad divider-former process and our complete Nova Trad delayed proofing process. Our tray-loading machine can work with different sized dough trays, but also with flat trays or even with the dough received directly into a mold.

PRODUCTION CYCLE :

With a production cycle of 10 minutes, DOLINE is capable of de-vatting and loading into trays a 200kg batch of dough. At this rate, up to 15 mixers can be processed in a single working day (7 hours), without the need for manual de-vatting, and with consistent results, whatever the operator.

The speed of the process enables bakers to optimize their working time and maximize their yield.

-

VOLUMETRIC DIVIDER WITH PRESSURIZED HOPPER, A GUARANTEE OF CONSISTENCY.

With a capacity of 210 kg, the pressurized hopper guarantees seamless dough descent and high consistency from the first to the last tray (+/-2%). The volumetric divider, equipped with a 110mm-diameter piston, enables precise dough division. The weight of the dough pieces can be adjusted from 400 to 1200 g from the divider’s handwheel. Doline’s three speeds can be adjusted depending on the weight and speed required, offering flexibility adapted to the operator’s needs.

-

QUALITY AND HOMOGENEITY, OPTIMAL DOUGH ROUNDING.

Once the dough pieces have been divided, they are automatically floured before passing under the bar belt, which gathers them together and facilitates their transport to the rolling machine. The integrated rolling machine ensures uniformity and gentle shaping, with true respect for the dough and without excessive degassing. It imitates manual folds perfectly, guaranteeing a beautifully developped final dough piece.

-

SIMPLIFIED CLEANING AND MAINTENANCE

Cleaning and maintenance are made easy thanks to dedicated programs accessible from the touch control. Antistatic blue belts, designed to limit the adhesion of residues, are easily vacuumed and cleaned. Maintenance is optimized with access points for adding flour or dough without the need for tools. An integrated flour recovery system contributes to maintaining a clean and efficient working environment.

COMFORT & PRODUCTIVITY :

DOLINE is a compact, ergonomic, highperformance dough-loading solution that saves time, respects the product and ensures consistency, while adapting to the requirements of bakers. Ideal for compensating for staff shortages and optimizing productivity, its automated settings make management simlpe. Only one operator is needed to run Doline.

ERGONOMICS & COMFORT :

DOLINE considerably improves the ergonomics of a particularly physically demanding workstation, by automating the manual de-vatting of the mixer, thus reducing operator fatigue and unpleasant postures. A warning system with tricolour light (green: running, orange: defect, red: fault) provides a quick and intuitive display of the machine’s status.

FLEXIBLE, OPTIMIZED INTEGRATION :

DOLINE can be easily integrated into any type of laboratory, thanks to its compact footprint and modular design. Its components, mounted on wheels, offer great flexibility, making it easy to move and adapt to site constraints.

The gravity conveyor can be easily reconfigured, aligned with the tray conveyor or oriented at 90°, to adapt perfectly to the organization and production flow. DOLINE can also be combined with an automatic group (for doughs up to 65% hydration and a minimum doughpieces weight of 200g).

Key figures:

- 15 mixers per day

- From 1 to 6 trays / min

- Trays from 1 kg to 7 kg

- Dough pieces from 400 g to 1200 g

- For all types of dough, even the most hydrated (up to 75% depending on process and flour)

-

Automatic brioche machine

+More information

Automatic brioche machine

+More information

-

Automatic pizza line

+More information

Automatic pizza line

+More information

-

Archipel - Automatic bread plant

+More information

Archipel - Automatic bread plant

+More informationARCHIPEL is an automatic bread plant composed of four equipments: a volumetric divider, a conical rounder, an intermediate proofer and a moulder. Its...