Catalogue de nos machines et pétrins pour la boulangerie

Parce que tous les pains ne se ressemblent pas, que tous les équipements ne se valent pas et que tous les boulangers n’ont pas les mêmes besoins, BERTRAND PUMA vous propose plusieurs gammes et finitions sur ses équipements afin qu’ils soient précisément adaptés à tous les fournils. Les versions Platinium et Stentor de nos équipements se démarquent par les caractéristiques suivantes :

Elle vous permet d’accéder aux options les plus techniques.

Elle assure le fonctionnement pour un travail toujours plus précis et un résultat inégalable dans le fournil. La réponse à l’exigence des professionnels qui visent toujours le résultat supérieur.

C’est le choix de la technologie pour les boulangers de la modernité.

Accéder à une conception renforcée et un choix de matériaux et d'accessoires toujours plus robuste.

Pour une utilisation intensive, tout terrain, tout au long de la journée.

C'est le choix de la performance à chaque instant, dans toutes les conditions.

Elle vous fait accéder à une gamme de produits spécialement conçue pour les petits espaces.

C'est le choix d'un gain de place et de facilité d'utilisation pour votre boulangerie sans compromis sur la performance.

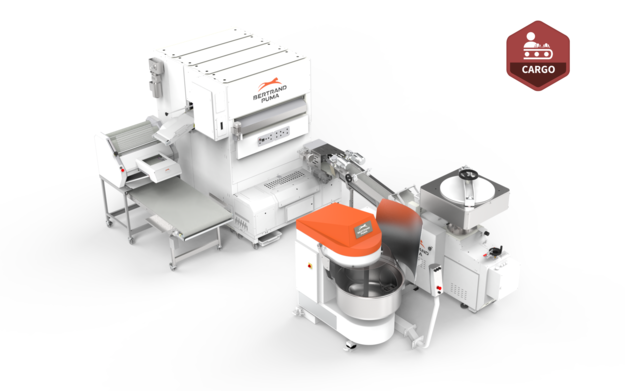

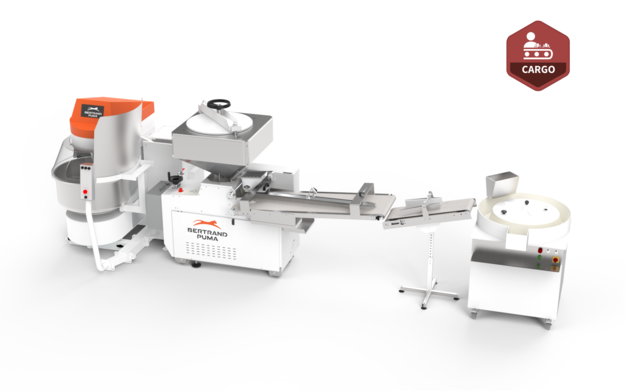

La gamme cargo regroupe des équipements robustes, fiables, réguliers et dimensionnés pour accepter des volumes et cadences de production de niveau semi-industriel.

Doline - Mise en bacs automatique

DOLINE est une machine tout inox conçue pour la mise en bacs de la pâte après pétrissage. La pâte, introduite manuellement ou via un pétrin autobasculant est, pesée, divisée et mise en bacs automatiquement.

Archipel - Groupe automatique

ARCHIPEL est un groupe automatique de panification composé de quatre équipements : une diviseuse volumétrique, une bouleuse conique, une chambre de détente intermédiaire et une façonneuse. Sa conception compacte et sa facilité d’utilisation et d’entretien la rende adaptée aux petites comme aux grandes boulangeries.

Avec une capacité allant jusqu’à 1200 pièces/heure, ce système automatisé quatre en un produit des baguettes et pains variés de haute qualité.

Diviseuse bouleuse automatique et semi-automatique - Alizé

La gamme des ALIZÉ sont des Diviseuses-Bouleuses, parfaites pour diviser et bouler des pâtes de tous types et de tous poids, sans altération du processusde pousse de la pâte. Elles se déclinent en version semi-automatique (Stentor) et automatique (Platinium), avec 4 modèles allant de 15 à 36 divisions.

Pétrin à spirale cuve fixe Oxygene

Les pétrins à spirale de la gamme OXYGENE offrent une qualité de pétrissage incomparable. La gamme se décline en 5 modèles, d’une capacité de pâte maximum allant de 45 à 200kg.

Dynamiseurs d'eau VOLUTE et TORRENT

Les Dynamiseurs d’eau de la gamme Bertrand Puma ont une impressionnante capacité de traitement et offrent un approvisionnement rapide et constant en eau purifiée, dynamisée et structurée.

Le système de filtration est conçu pour réduire significativement la présence de métaux lourds, de pesticides, tout en préservant les minéraux essentiels et en éliminant le chlore.

Avec une filtration de pointe et un processus de dynamisation et structuration de l’eau, ils garantissent une eau saine pour la production de produits de qualité.

Fermentolevain

Le Fermentolevain est un équipement de boulangerie-pâtisserie permettant d’élaborer et de conserver du levain liquide.

L’incorporation de levain liquide en panification permet de raccourcir les temps de pétrissage et de favoriser un alvéolage irrégulier. Le levain liquide confère une plus grande tolérance mécanique aux pâtes (souplesse, allongement). En fonction du pourcentage d’incorporation, les arômes et les saveurs des produits seront variés.

Pétrin à bras plongeants Abyss

Les pétrins à bras plongeants ABYSS reproduisent parfaitement le geste de l’artisan en pétrissant délicatement tous types de pâtes — des plus hydratées aux plus complexes — pour une oxygénation optimale sans échauffement.

Laminoir STRATUS

Les laminoirs stratus sont disponibles sous plusieurs tailles : Junior (à poser sur table), Sénior et Sénior XL. Ils permettent d’affiner les pâtes et de réaliser de beaux feuilletages.

Tornado 80

Le batteur mélangeur Tornado 80 de Bertrand Puma a été conçu spécifiquement pour les productions intensives en boulangerie-pâtisserie, le batteur mélangeur Tornado possède une capacité de cuve de 80 litres.

Gage de productivité et de confort grâce à sa construction robuste et ergonomique, ainsi qu’à ses outils interchangeables, Tornado vous offre une grande polyvalence dans la réalisation de vos produits.

Divitrad

La légendaire DiviTrad®, utilisée depuis tant d’années, revient en force avec un tout nouveau design et de nouvelles fonctionnalités, sous le nom de DiviTrad® Legend.

Polyvalente, DiviTrad® est équipée de couteaux permettant une coupe en 20 pâtons carrés. Elle permet aussi bien la division «classique» avant fermentation que la division «tradition» pour travailler en direct et cuire immédiatement.

Batteur Mélangeur Tornado Touch

Conçus spécifiquement pour la boulangerie et la pâtisserie, les batteurs mélangeurs de la gamme Tornado se déclinent en 2 modèles d’une capacité de 40 (Tornado Touch) ou 60 litres (Tornado).

Laminoir Stratus Mega 1400/1600

Les STRATUS Mega sont des laminoirs automatiques tout inox destinés à la transformation de la pâte pour la réalisation de viennoiseries et pâtisserie.

Batteur Mélangeur TORNADO COMPACT

Ce batteur sur table est l’atout idéal pour les petits espaces, notamment en pâtisserie, permettant de faire des crèmes, mélanges, ou différentes pâtes.

Enrouleuse Nova Soft

L’enrouleuse Nova Soft permet d’allonger les pâtons sans les dégazer afin d’assurer un développement de qualité aux produits, des bouts arrondis et préserver l’alvéolage.

Pétrin à spirale auto-basculant

Le pétrin auto-basculant de Bertrand Puma permet de transférer la pâte contenue dans la cuve fixe.

Le pétrin est entièrement soulevé puis incliné par le bras mécanique de manière à faire glisser la pâte contenue dans la cuve vers une peseuse volumétrique ou une table d’affalage.

Façonneuse Euro 2000 (verticale)

La façonneuse Euro 2000 permet le laminage et le façonnage des pâtons destinés à la fabrication de baguettes, de gros et petits pains longs.

Pétrin à spirale à cuve amovible

Équipé de deux vitesses de rotation, le pétrin à cuve amovible est conçu pour éviter les remontées de pâtes, et de contrôler précisément la vitesse de pétrissage en fonction de la force de la pâte.

Diviseuse hydraulique equinoxe

L’Equinoxe est l’alliée des productions intensives, capable de diviser la pâte en 20 pâtons égaux tout au long de la journée.

De plus elle est homologuée par le Lempa pour son système réduisant les projections de farine. Elle donne ainsi accés aux aides jusqu'à 50% d'investissement (voir sur le site ameli.fr).

Elevateur de cuve

Les pétrins à spirale à cuve amovible peuvent bénéficier d’un élévateur de cuve afin de décuver plus facilement les différents produits.

Repose-pâtons Eclipse

Le Repose pâtons Eclipse est une chambre de détente intermédiaire à balancelles, favorisant l’allongement au moment du façonnage.

Chambre de détente BP

La chambre de détente BP est déclinée en version automatique ou manuelle, de 62 à 84 balancelles, en 2 largeurs, permettant d’atteindre une capacité de 260 à 588 pâtons.

Diviseuse hydraulique equinoxe compact

Grâce à l’Equinoxe Compact, les artisans boulangers peuvent compter sur une machine compacte sachant s‘intégrer à leurs petits espaces de travail, et qui conserve le niveau de robustesse et de performance qu’ils recherchent au quotidien.

Divitrad Compact

La légendaire DiviTrad® se décline désormais en mode Compact ! Avec une profondeur de 810 mm pour une largeur de 680 mm avec son cadre (châssis de 510 mm de large), la DiviTrad® Compact saura se faire une place dans les fournils les plus restreints, tout en conservant le niveau de robustesse et de performance attendu au quotidien.

Avec sa cuve de 400x400 mm, DiviTrad® Compact est équipé de couteaux permettant une découpe en 20 pâtons carrés. Elle permet aussi bien la division «classique» avant fermentation que la division «tradition» pour former des baguettes et cuire immédiatement.

Diviseuse hydraulique à cuve ronde

La D20R est une diviseuse hydraulique à cuve ronde, capable de diviser la pâte en 20 pâtons égaux. Tout comme les autres diviseuses, le design et les matériaux utilisés dans la construction de la D20R sont pensés pour en faciliter l’entretien.

Diviseuse Bouleuse RD2 First

L’utilisation d’une diviseuse bouleuse permet la division de la pâte en pâtons de masse égale et un boulage pour la réalisation de petits pains ronds.

Peseuse volumétrique

La peseuse volumétrique « HT » est une machine robuste, précise et d’une grande productivité, pouvant diviser de 900 à 2200 pièces/heure, à une cadence fixe ou variable.

Laminoir cadet

Les laminoirs Cadet sont des laminoirs sur table. Ils sont équipés de tablettes fixes en inox.

Bouleuse à bande et tapis de liaison

Les bouleuses à bandes BERTRAND PUMA sont destinées à bouler les pâtons venant d’être divisés. Le boulage favorise une pré-fermentation ainsi qu’une fermentation régulière et homogène.

Balancelle manuelle à façonneuse intégrable RPFI

Tout intégré, cet équipement permet aussi bien la détente des pâtons que le façonnage. La RPFI est mobile grâce à des roulettes (dont 2 freins) implantées sous le châssis.